A pump application might need to cover several duty points, of which the largest flow and/or head will determine the rated duty for the pump. A control and regulation system is important in a pumping system so as to optimise the duty working conditions for the head pressure and the flow. It provides:

●process control

●better system reliability

●energy savings.

For any pump with large flow or pressure variations, when normal flows or pressures are less than 75 % of their maximum, energy is probably being wasted from excessive throttling, large bypassed flows (either from a control system or deadhead protection orifices), or operation of unnecessary pumps.

The following control techniques may be used:

●shut down unnecessary pumps. This obvious but frequently overlooked measure can be carried out after a significant reduction in the plant’s use of water or other pumped fluid (hence the need to assess the whole system)

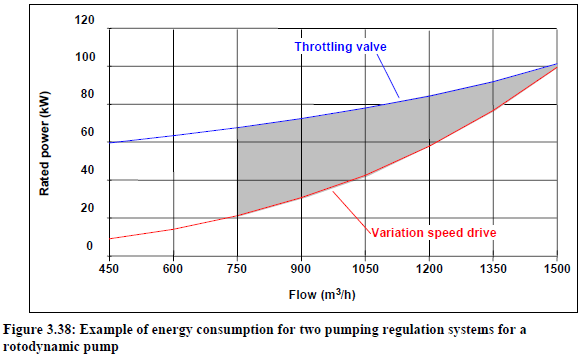

●variable speed drives ( on the electric motor) yield the maximum savings in matching pump output to varying system requirements, but they do have a higher investment cost compared to the other methods of capacity control. They are not applicable in all situations, e.g. where loads are constant (see Section 3.6.3)

●multiple pumps offer an alternative to variable speed, by pass, or throttle control. The savings result because one or more pumps can be shut down when the flow of the system is low, while the other pumps operate at high efficiency. Multiple small pumps should be considered when the pumping load is less than ha lf the maximum single capacity. In multiple pumping systems, energy is commonly lost from bypassing excess capacity, running unnecessary pumps, maintaining excess pressure, or having a large flow increment between pumps

●controlling a centrifugal pump by throttling the pump discharge (using a valve) wastes energy. Throttle control is, however, generally less energy wasteful than two other widely used alternatives: no control and by pass control. Throttles can, therefore, represent a means to save pump energy, although this is not the optimum choice.

泵浦的使用需因應不同的工作點,其最大流量及水頭高度決定其額定工作容量。所以泵輸系統需要有一套控制與調節系統來優化其流量與水頭壓力等工作條件。系統可以作到:

●製程控制

●較佳的系統可靠度

●節能

使用的泵浦如有很大的流量與壓力變化,其正常使用流量及壓力若低於其最大值之75%以下,會因過多的節流、大量的旁通流量(自控制系統或防止空轉孔流)或讓不需使用的泵浦運轉而造成能源損失。

下列控制技術可用來避免上述現象:

●把不需要的泵浦關掉:在一座工場明顯減少用水或其他流體後,一項往往被忽略執行的工作。

●在電動馬達上採用變速驅動裝置:這樣可以讓泵浦產出配合不同系統需求而達到最大節能。但這會比其他容量控制的方式投入更高資金成本。這方法並非適合所有情況,例如定容的負載條件就不適用。

●複數泵浦:可替代加裝變速裝置旁通閥或其節流方法。其節能來自當系統需要的流量降低時可關閉一台或數台,而讓其他台以高效率方式繼續運轉。

●以泵浦出口節流閥方式控制離心泵:此作法固然也是浪費能源,但與其他兩種方式:不加控制和以旁通回流的能耗要少許多。這說明節流也是泵浦省能的方法,但不是最好的辦法。

None reported.

無

The applicability of particular measures, and the extent of cost savings depend upon the size and specific nature of the installation and system. Only an assessment of a system and the installation needs can determine which measures provide the correct cost-benefit. This could be done by a qualified pumping system service provider or by qualified in-house engineering staff.

The assessment conclusions will identify the measures that are applicable to a system, and will include an estimate of the savings, the cost of the measure, as well as the payback time.

一些特別的使用方法及節省的成本端視設施和系統的規模與特性而定。只有評鑑過系統及設施才能決定其正確的成本效益。此評鑑可由合格的泵輸系統服務供應商或合格的公司內部工程師來執行。

評鑑結論可用來辨明系統該使用何種方法、估計節省的成本、實施成本及回收年限等資料。

Pumping systems often have a lifespan of 15 to 20 years, so a consideration of lifetime costs against initial (purchase) costs are important.

Pumps are typically purchased as individual components, although they provide a service only when operating as part of the system, so a consideration of the system is important to enable a proper assessment of the cost-benefit.

通常泵浦系統有較長的使用年限(15~20年),所以全使用年限的成本和初設成本間的考量是很重要的。

一般而言,泵浦都是單獨採購的,雖然在系統內可提供部分功能,但系統在評估成本效益時,泵浦的購置成本應考量在內。

Energy Efficiency (2009) 3.8.5