The information on Achieved environmental benefits, Cross-media effects, Applicability, Economics, Driving forces for implementation, Examples, and Reference information for ENE techniques for electric motors is given in Section 3.6.7.

Energy efficient motors (EEMs) and high efficiency motors (HEMs) offer greater energy efficiency. The additional initial purchase cost may be 20 - 30 % or higher for motors of greater than 20 kW, and may be 50 - 100 % higher for motors under 15 k W, depending on the energy savings category (and therefore the amount of additional steel and copper use) etc. However, energy savings of 2 - 8 % can be achieved for motors of 1 - 15 kW.

As the reduced losses result in a lower temperature rise in the motor, the lifetime of the motor winding insulation, and of the bearings, increases. Therefore, in many cases:

●reliability increases

●downtime and maintenance costs are reduced

●tolerance to thermal stresses increases

●ability to handle overload conditions improves

●resistance to abnormal operating conditions − under and overvoltage, phase unbalance, poorer voltage and current wave shapes (e.g. harmonics), etc. – improves

●power factor improves

●noise is reduced.

A European-wide agreement between the European Committee of Manufacturers of Electrical Machines and Power Electronics ( CEMEP) and the European Commission ensures that the efficiency levels of most electric motors manufactured in Europe are clearly displayed. The European motor classification scheme is applicable to motors < 100 kW and basically establishes three efficiency classes, giving motor manufacturers an incentive to introduce higher efficiency models:

●EFF1 (high efficiency motors)

●EFF2 (standard efficiency motors)

●EFF3 (poor efficiency motors).

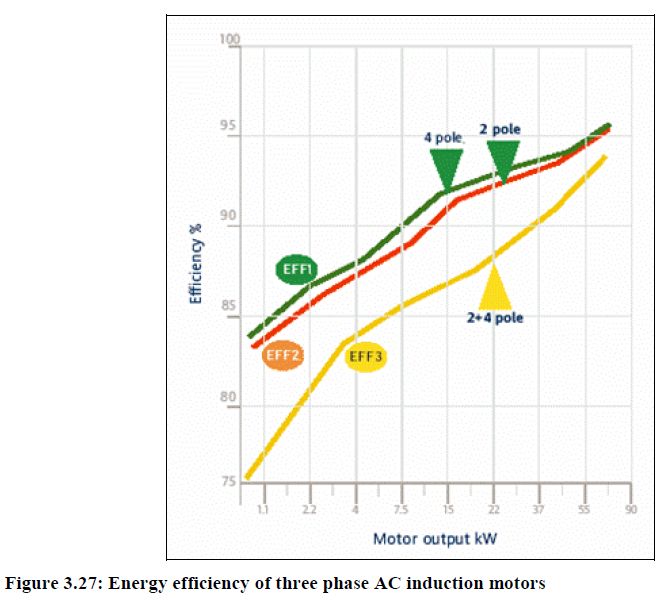

These efficiency levels apply to 2 and 4 pole three phase AC squirrel cage induction motors, rated for 400 V, 50 Hz, with S1 duty class, with an output of 1.1 to 90 k W, which account for the largest sales volume on the market. Figure 3.27 shows the energy efficiency of the three types of motors as a function of their output.

The Eco Design (EuP) Directive is likely to eliminate motors in class EFF 3 and EFF 2 by 2011. The International Electrotechnical Comission ( IEC) is, at the time of writing, working on the introduction of a new international classification scheme, where the EFF2 and EFF# motors are together at the bottom, and above EFF1 there will be a new premium class.

An appropriate motor choice can be greatly aided through the use of adequate computer software, such as Motor Master Plus29 and EuroDEEM30 proposed by the EU-SAVE PROMOT project.

Appropriate motor solutions may be selected by using the EuroDEEM database31, which collates the efficiency of more than 3500 types of motors from 24 manufacturers.

使用高效型馬達(EEM和HEM)具較高的能源效率。以大於20kW的馬達而言,初始購置成本會高出20~30%;小於15kW的馬達則會高出50~100%,要看馬達的節能類別和製造使用鐵、銅等材料多少而定。不過以1~15kW的馬達來看,可以節省2~8%能源。

由於減少損失的結果,使得馬達運轉的溫度較低,如此有利於馬達繞線的絕緣和轉動軸承的使用年限增長,所以會有下列好處:

●可靠度提升

●停機維修時間和成本降低

●機械對熱應力的容忍度增高

●對於過載運轉的應對能力增強

●對於如過低或過高電壓、相間不平衡、電壓及電流波形失準(諧波)等不正常的操作條件下,其對應能力增強

●功率因素提升

●減少噪音

歐盟電機電子製造商協會(CEMEP)和歐盟委員會(EC)間的電動馬達效率水準協議,已明確地公告且適用於全歐洲。基本上,歐盟馬達分為三個效率水準,而且適用小於100kW的馬達,這讓馬達製造商有生產較高效率馬達的誘因。

●EFF1 (高效率馬達)

●EFF2 (標準效率馬達)

●EFF3 (低效率馬達)

歐盟馬達效率分類應用於2極/4極三相50Hz交流鼠籠式感應馬達、額定電壓400伏特、S1級工作類別、出力在1.1~90kW的馬達,是在歐洲地區市占率最高的馬達。圖3.27顯示這三類能效分類馬達出力情形。

歐盟環保設計指引(EuP)中要把第三級馬達汰除,至於第二級則在2011年起淘汰。國際電力技術委員會(IEC)在訂定ENE最佳可行技術時,正作業訂定新的國際分類,將把EFF2及EFF#馬達放在最末級,然後在EEF1之上將有更高級的類別。

可利用合適的電腦軟體協助馬達的選用。

Harmonics caused by speed controllers, etc. cause losses in motors and transformers ( see Section 3.5.2). An EEM takes more natural resources (copper and steel) for its production.

●運轉控制器形成的諧波造成馬達和變壓器損失

●高效型馬達生產時需耗用更多的自然資源(銅、鐵)

Electric motor drives exist in practically all industrial plants, where electricity is available.

The applicability of particular measures, and the extent to which they might save money, depend upon the size and specific nature of the installation. An assessment of the needs of the entire installation and of the system within it can determine which measures are both applicable and profitable. This should be done by a qualified drive system service provider or by qualified in-house engineering staff. In particular, this is important for VSDs and EEMs, where there is a risk of using more energy, rather than savings. It is necessary to treat new drive application designs from parts replacement in existing applications. The assessment conclusions will identify the measures which are applicable to a system, and will include an estimate of the savings, the cost of the measure, as well as the payback time.

For instance, EEMs include more material (copper and steel) than motors of a lower efficiency. As a result, an EEM has a higher efficiency but also a lower slip frequency ( which results in more rpm) and a higher starting current from the power supply than a motor of standard efficiency. The following examples s how cases where using an EEM is not the optimum solution:

●when a HVAC system is working under full load conditions, the replacement of an EEM increases the speed of the ventilators ( because of the lower slip) and subsequently increases the torque load. Using an EEM in this case brings about higher energy consumption than by using a motor of standard efficiency. The design should aim not to increase the final rpm

●if the application runs less than 1000 − 2000 hours per year (intermittent drives), the EEM may not produce a significant effect on energy savings (see Economics, below)

●if the application has to start and stop frequently, the savings may be lost because of the higher starting current of the EEM

●if the application runs mainly with a partial load (e.g. pumps) but for long running times, the savings by using EEM are negligible and a VSD will increase the energy savings.

只要在有電力可用的地方,用電動馬達作為動力帶動在產業界是相當普遍的。

電動馬達的應用性及節省的成本要看設施的特性和規模而定。針對整體設施及系統需求評估,以決定其引入方法之可行性及價值。這項評估可由品質管理系統服務機構或由公司內部工程部門人員進行。

尤其是像變速設備(VSD)和能效型馬達(EEM)的使用有能耗更大而無法省能的風險,因此必須慎重。在更換現有設備零件時有必要採用新驅動設備。評估結果可用來研判何種方法可應用於系統中,及投入成本、節省成本、回收年限等資訊。

例如高能效型馬達(EEM)要用比低效型馬達更多的銅鐵材料,結果EEM雖有較高效率,但同時會有較低的轉差頻率(slip freq.)造成馬達轉速加快,以及比標準型馬達需要更大的起動電流。

以下有些例子說明不適合使用EEM的情況:

●當一套全載運轉的空調系統換裝EEM會因為低轉差頻率而增加通風器的轉速,進而增加轉動扭矩負荷。因此,使用EEM反而較標準型馬達更耗能,這設計不應該用來增加最後的轉速。

●如果設備每年運轉時數少於1000~2000小時,裝設EEM無法有顯著的節能效果。

●若設施必須經常性起停,可能會因EEM需要高起動電流而無法節省費用。

●若設施主要運轉模式為長時間半載運轉(如泵浦),使用EEM的節省幅度微乎其微,還不如用VSD可以省能。

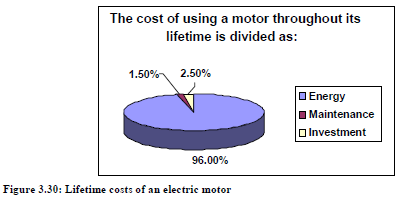

The price of an EEM motor is about 20 % higher than that of a conventional one Over its lifetime, approximate costs associated with operating a motor are shown in Figure 3.30:

When buying or repairing a motor, it is really important to consider the energy consumption and to minimise it as follows:

●payback period can be as short as 1 year or less with AC drives

●high efficiency motors need a longer payback on energy savings.

能效型馬達較傳統型價格高約20%,其使用年限、操作成本如圖3.30。

當考慮要新購或修理馬達時要慎重地考量能效和下列事項:

●交流驅動馬達的回收年限可低於一年

●高效率馬達在能源節省上需要較長的回收年限

Energy Efficiency (2009) 3.6.1