Recuperative and regenerative burners have thus been developed for direct waste heat recovery through combustion air preheating. A recuperator is a heat exchanger that extracts heat from the furnace waste gases to preheat the incoming combustion air. Compared with cold air combustion systems, recuperators can be expected to achieve energy savings of around 30 %. They will, however, normally only preheat the air to a maximum of 550−600 °C. Recuperative burners can be used in high temperature processes (700−1100 °C).

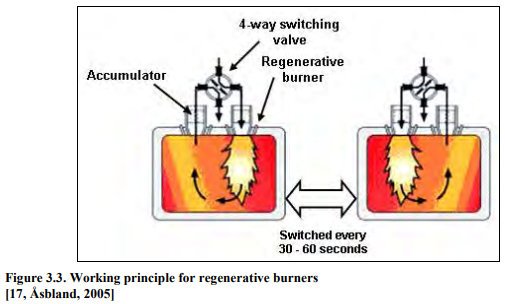

Regenerative burners operate in pairs and work on the principle of short term heat storage using ceramic heat regenerators, see Figure 3.3. They recover between 85−90 % of the heat from the furnace waste gases; therefore, the incoming combustion air can be preheated to very high temperatures of up to 100− 50 °C below the furnace operating temperature. Application temperatures range from 800 up to 1500 °C. Fuel consumption can be reduced by up to 60 %.

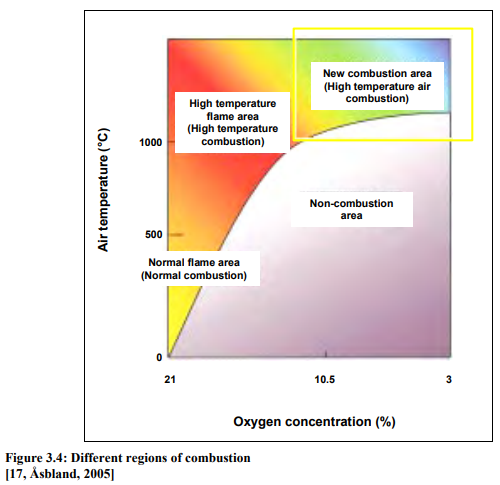

Recuperative and regenerative burners (HiTAC technology) are being implemented in a novel combustion mode with homogeneous flame temperature (flameless combustion, see Section 5.1), without the temperature peaks of a conventional flame, in a substantially extended combustion zone. Figure 3.4 shows the different regions of combustion at varying oxygen concentrations and air temperature.

同流換熱式燃燒器和回熱式燃燒器的發展是將燃燒廢熱以空氣預熱的方式直接回收。同流換熱器是一種熱交換器,可直接從燃燒爐的廢氣中攫取熱能來預熱燃燒進氣空氣。

和一般冷空氣進氣燃燒比較,同流換熱器可節省約30%的熱能,但正常情況下,預熱空氣最多只能到550−600 °C,同流換熱器可用在700−1100 °C的高溫製程。

回熱式燃燒器是一對一裝設的陶瓷材質再生器,主要用在前儲熱系統,它可從燃燒爐廢氣中回收85-90°C的熱能,所以燃燒進氣空氣可以被預熱到比燃燒爐的操作溫度低100−150 °C的高溫,可應用在操作溫度範圍從800~1500°C,最多可節省燃料消耗60%。

同流換熱式燃燒器和回熱式燃燒器(高溫空氣燃燒技術)是較新穎的燃燒模式(無焰燃燒)中,均質火燄溫度的分佈在燃燒區塊,不似傳統燃燒有焰峰出現。

圖3.4表示不同的氧氣濃度及空氣溫度時,不同的燃燒區塊。

The important constraint of state-of-the-art recuperative/regenerative burner technology is the conflict between technologies designed to reduce emissions and to focus on energy efficiency. The N Ox formation, for fuels not containing nitrogen, is basically a function of temperature, oxygen concentration, and residence time. Due to high temperatures of the preheated air, and the residence time, conventional flames have high peak temperature which leads to strongly increase NOx emissions.

現代工藝的同流換熱式燃燒和回熱式燃燒技術有項重要的條件限制,就是技術設計、減排和能源效率間的衝突,在使用不含氮的燃料時,基本上NOx的形成來自溫度的作用。由於使用高溫將空氣預熱,含氧濃度及停留時間長短,傳統的燃燒火焰有高焰峰溫度,導致NOx排放的增加。

Widely used

廣泛使用

A drawback with these burners is the investment cost. The decreased costs for energy can rather seldom alone compensate the higher investment cost. Therefore, higher productivity in the furnace and lower emissions of nitrogen oxides are important factors to be included in the cost benefit analysis.

這些燃燒器的投資成本高是一缺點。從能源這邊節省的成本很難彌補高投資成本。所以加熱爐的高生產力和低NOx排放兩項因素在分析成本效益時必須納入。

Energy Efficiency (2009) 3.1.2