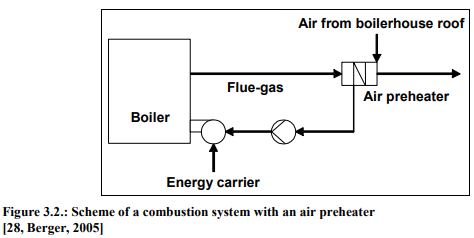

Besides an economiser ( Section 3.2.5), an air preheater (air-air heat exchanger) can also be installed. The air preheater or APH heats the air which flows to the burner. This means flue- gases can be cooled down even more, as the air is often at ambient temperature. A higher air temperature improves combustion, and the general efficiency of the boiler will increase. In general for every decrease of 20 °C in flue-gas temperature, a 1 % increase in efficiency can be achieved. A scheme of a combustion system with an air preheater is shown in Figure 3.2.

A less efficient but simpler way of preheating might be to install the air intake of the burner on the ceiling of the boilerhouse. Generally, the air here is often 10 to 20 °C warmer compared to the outdoor temperature. This might compensate in part for efficiency losses.

Another solution is to draw air for the burner via a double walled exhaust pipe. Flue-gases exit the boiler room via the inner pipe, and air for the burner is drawn via the second layer. This can preheat the air via losses from the flue-gases.

Alternatively, an air-water heat exchanger can be installed.

燃燒系統除裝設節煤器(節能器)外,也要裝設燃燒空氣預熱器(空氣熱交換器)。空氣預熱器(APH)把要進入燃燒器的空氣加熱,同時把煙氣溫度降低ㄧ些。高溫的進氣可以提升燃燒效果,所以可以提升鍋爐效率。ㄧ般而言,煙氣每降低20°C,約可增加1%的燃燒效率。裝有空氣預熱氣的燃燒系統如下圖3.2。

一個較為簡單但效果沒那麼好的空氣預熱方法,將燃燒器空氣的進氣口設在鍋爐房的上方, 通常那裡空氣會比室外溫度高10~20 °C,這方式也可補償部分效率的損失。

另外一種方法是煙氣鍋爐房利用雙套管排出,內管走煙氣,外管走空氣,將空氣預熱後熱空氣為燃燒器進氣,以降低損失。

同樣的,飼水與空氣的熱交換器也可以這麼做。

There are, however, also some practical disadvantages related to an APH, which often inhibit installation:

●the APH is a gas-gas heat exchanger, and thus takes up a lot of space. The heat exchange is also not as efficient as a gas-water exchange

●a higher drop pressure of the flue-gases means the ventilator of the burner has to provide higher pressure

●the burner must ensure that the system is fed with preheated air. Heated air uses up more volume. This also poses a bigger problem for flame stability

●there may be higher emissions of NOx due to higher flame temperatures.

APH有一些實務上的缺失,使APH不能裝設:

●APH 是一氣對氣的熱交換器需要很大的空間,其換熱效率也不及氣對水的熱交換。

●APH會造成煙氣更多的壓降,所以燃燒器的進風口壓力必須高一些。

●燃燒器的進氣空氣必須確定是預熱空氣,而且空氣要多些,這表示燃燒火焰的穩定性會有一些問題。

●由於較高的火燄溫度使得NOx的排放值較高。

The installation of an air preheater is cost effective for a new boiler. The change in air supply or the installation of the APH often is limited due to technical reasons or fire safety. The fitting of an APH in an existing boiler is often too complex and has a limited efficiency.

Air preheaters are gas-gas heat exchangers, whose designs depend on the range of temperatures. Air preheating is not possible for natural draught burners.

Preheated water can be used as boiler feed or in hot water systems (such as district schemes).

裝設APH對新鍋爐而言是具成本效益的;但改變空氣供應方式或裝設APH往往受到技術或防火安全的約制。既有的鍋爐系統要裝設APH,往往太複雜且效果有限。

APH是氣對氣的熱交換器,其設計依據溫度範圍, 且不適用於自然抽氣的燃燒器。

飼水預熱可用在鍋爐飼水或地區供熱系統的熱水供應。

In practice, the possible savings from combustion air preheating amount to several per cent of the steam volume generated, as shown in Table 3.4. Therefore, the energy savings even in small boilers can be in the range of several GWh per year. For example, with a 15 MW boiler, savings of roughly 2 GWh/yr, some EUR 30 000/yr and about 400 t CO2/yr can be attained.

實務上,燃燒空氣預熱可省下蒸汽產出量的幾個百分點,就算是小型鍋爐一年也可節省數GWh,,例如一座1.5MW的鍋爐每年大約省下2GWh,值30,000歐元並減少400噸的CO2排放。

Energy Efficiency (2009) 3.1.1.1